|

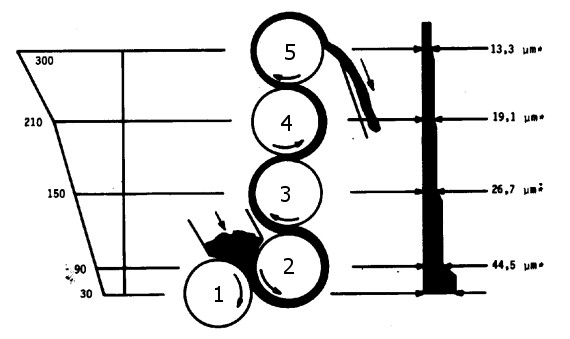

Particle size reduction can be obtained by roll refining. Figure 5.5 shows a diagram of the five-roll refiner. The viscous chocolate paste is fed through the gap between the two first rollers to be formed into a film of chocolate, and the particles are crushed, flattened and more or less torn apart. The lowest roller runs at the slowest rotational speed, while those above it are increasingly faster. The film of the product being refined always sticks to the faster-moving roller and moves upwards, from the first to the second roller, then from the second to the third etc. to be refined into increasingly smaller particles.

Figure 5.5: Schematic view of a 5-roller refiner

temperatures e.g.

roller 1 = 30° C

roller 2 = 35° C

roller 3 = 40° C

roller 4 = 45° C

roller 5 = 40° C

Hydraulic pistons press the first roller against the second lowest roller, which is fixed firmly in position, while the width of the working gap between them can be adjusted. Hydraulic pressure on the fifth and last roller causes dynamic pressure of the whole roller stack, i.e. rollers 5, 4 and 3, on the second roller.

The scraping knife fitted to the fifth roller scrapes off the film of refined product that is transported by a steel band conveyor to the next processing step.

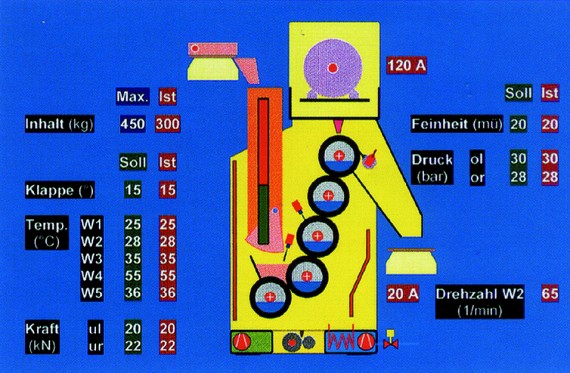

Figure 5.6: Graphical view of a 5-roller refiner (SLFA)

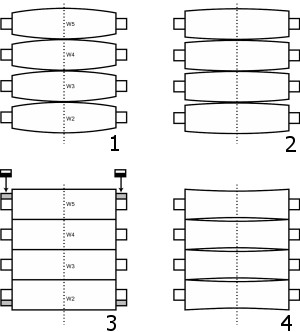

With the film of the product passing between the rollers, the hydraulic-generated pressure causes them to, so to speak, flow on each other (this can be compared to aquaplaning). Due to the pressure of the product passing between them, the rollers bend and, if not corrected, the product film would be thicker at the centre than at either end. For this reason, curved rollers are used, which are a little wider at the centre, but will be straightened by the ultimate load, thereby ensuring an even spread of the film over the whole surface of the roller (Figure 5.7). It is important to bear in mind that this construction requires a pre-fixed operating pressure and that, unlike what is sometimes thought, the fineness of the particles cannot be constantly changed by adjusting the roll pressure.

Figure 5.7: Roller underpressure (1), too low pressure (2), correct pressure(3) and too high pressure (4)

The system can be adjusted to the properties of the raw materials to ensure a constant quality of the end product.

Taking into account the curved shape of the roller, several adjustments are possible for achieving the ultimate degree of fineness:

- adjustment of the first roller, such that it produces a particle size sufficiently small for the product to retain its plasticity, thereby ensuring good pulling in by the fifth roller.

- with each subsequent passage through the rollers, the total surface of the

particles increases and the product becomes increasingly drier; to ensure a

certain degree of plasticity of the material and optimum pulling in by the

rollers, each roller is heated to a temperature a little higher than that of the

preceding one; only the last roller is a little colder to make the paste suitable

for being scraped off; changes in temperature may affect the plasticity and, consequently, the ultimate fineness of the material;

- the amount of paste that is pulled in and, consequently, the ultimate fineness of the material, depends on the width of the first refining slit;

- to enable adjustment of the product feed required to obtain the ultimate

fineness, a separate adjustable drive can be fitted on the second roller to

change its rotation speed; this, in combination with a measuring device for

permanent film measurement, enables automatic fineness control.

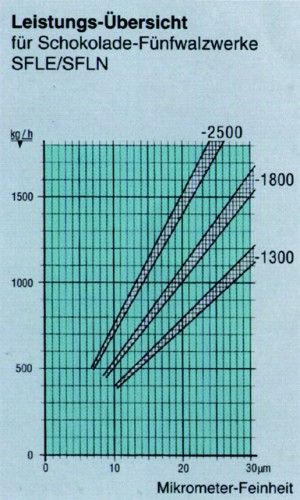

Figure 5.8: Refiner capacity versus fineness with a 2 steps refiner system

Figure 5.9: Electronic controlled 5-roller refiner (Bühler)

The temperature of the hollow rollers can be adjusted by injecting cooling water.

The end product of the roll refining process is a powdery material that, when heated, will become softer, but not actually melt as, because of the enlarged total surface of the particles, there is too little cocoa butter left to act as the continuous phase.

The centrifugal refiner and the ball mill are other methods for grinding.

The centrifugal refiner

In the McIntyre refiner conche, the solid particles in the chocolate are refined by steel grinding bars that scrape along the serrated inside wall of the cylinder. During the process the pressure on the grinding bars is gradually increased to grind the material into increasingly finer particles. The ultimate fineness of the chocolate also depends on the processing time, and the longer this is, the finer the chocolate.

For the best performance the chocolate paste must have a fair degree of liquidity as well as a relatively high fat content compared to the product from the roll refiner. Also in comparison with the roll refiner, the particle-size distribution in the centrifugal refiner is wider. This hampers dehumidification. A larger number of fine particles is produced, which impairs the ultimate rheological properties of the chocolate, with high cocoa butter consumption as a result.

However, the purchase price of the refiner/conche is relatively low and this, in combination with the machine’s ability to process small batches, i.e. a minimum batch size of 500 kg, makes this method eminently suitable for small-scale production.

Centrifugal refiners can be used for the production of both chocolate and compounds, i.e. imitation chocolate products on the basis of other fats.

The ball mill

Ball mills find wide application in the processing industry and can be used for the manufacture of relatively high-fat chocolate.

Via an intermediate tank, the chocolate mass is fed a number of times through the ball mill, i.e. a cylinder partly filled with steel balls rotated by a high-speed stirring gear. The chocolate is pumped in at the bottom and flows out at the top through a mesh small enough not to allow the balls to go through. Such factors as the operating speed, the pumping speed, the diameter, the weight of the balls and the composition of the chocolate all influence the end result.

Figure 5.10: Schematic view of Lehmann process

Today, Wiener, Lehmann and a number of other manufacturers supply several types of machine where the tank, mixing equipment, pump, grinding unit (ball mill), lecithin dosing equipment and de-humidification unit are incorporated into one system: the raw materials are fed in at one end to be discharged as chocolate at the other.

|