|

The conche has always been given a great deal of attention in traditional chocolate manufacture, conching being the phase where the volatile acids originally present in cocoa components are removed and where the moisture content is reduced, thereby allowing the delicate chocolate flavour to develop. It is this reduced moisture content in particular that is favourable for the rheological properties and the shelf-life of the product. A high fat content and the presence of lecithin, i.e. an emulsifier that can form a compound with water, retard the evaporation of water in chocolate, as well as the volatilization of acids. For this reason, de-moisturizing takes place more rapidly in a roll-refined chocolate than in a product manufactured by a total system. It also explains why dry conching has become popular: moisture evaporates more rapidly from a dry, i.e. low-fat, paste.

Conching is also important for making chocolate homogeneous, an aspect discussed later on.

When conching milk chocolate care should be taken that the conching temperature does not rise too high as this considerably increases the risk that reactions take place between milk proteins and sugars, thus bringing about undesirable changes in smell and flavour. A temperature of 60°C is recommended as an indication, while 70°C is the most usual temperature for conching dark chocolate.

The original conche (concha is the Spanish term for shell) was a shell-shaped trough, with a heavy granite roller that was moved backwards and forwards over a flat granite bed. Later on, this piece of machinery became known as Längsreiber or longitudinal conche. Although many claim that this method is unrivalled in the flavour it is able to produce, it has almost entirely fallen into disuse because of the very lengthy conching times that are required, and which may run up to - according to reports - even three or four days.

Using modern conches the chocolate manufacturer seeks to bring about flavour effects identical to those that could be obtained with the melangeur and the traditional conche, however in a shorter time. An important aspect to take into account, however, is the role conching plays in the manufacture of chocolate: apart from giving the product the desired flavour, the process must ensure that the product, when eaten, is perceived as homogeneous, as well as providing good rheological properties in terms of both processing and flavour perception.

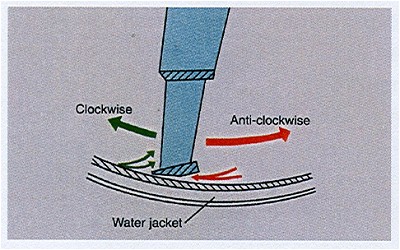

Figure 5.11: Principle of Längsreiber-conche as build by Lehmann

Flavour

During conching the volatile compounds, particularly the volatile acids, escape from the chocolate, and disappearance of part of them is desired. In addition, at relatively high temperatures (above 70°C), a great many chemical reactions take place during this process, all causing changes in the flavour pattern. For instance, the caramel flavour in milk chocolate can be made relatively stronger or weaker, and a ‘rounded’ flavour can be obtained by ‘rounding off’ the sugar particles and enclosing the solid particles in fat. These processes are traditionally carried out at temperatures from 80-85°C, and have lengthy processing times. Efforts to change this approach will demonstrate that chocolate flavour development is a largely unknown territory, and that shorter processing times do not automatically yield the same end result. Moisture, for instance, can play a role in the development of flavour components, and too fast a removal of it may inhibit this process.

Homogeneity

During roll refining the paste is pulled through very narrow slits, thereby refining it to the desired particle size, but also more or less flattening many particles that will, as a result, form large agglomerates. The considerable shearing force during conching causes these agglomerates to break up and distribute over the continuous fat phase, without further (undesirable) reduction of the particles taking place. This improves the homogeneity of the product, also in terms of its eating properties.

Rheological properties

In the roll-refining process, the paste is refined, but also, as it were, kneaded, however, not to a degree where the strongly enlarged total surface area of the particles is covered by a layer of fat; and it is this layer that is necessary to give the chocolate good rheological properties, while using the lowest possible amount of fat.

Another very important aspect of conching is moisture release as the presence of moisture affects the viscosity and yield value of chocolate; yet, it is often unavoidable that the relatively large amounts of moisture present in the raw materials add to the moisture content of the paste entering the roll refiner.

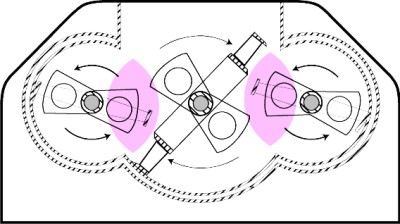

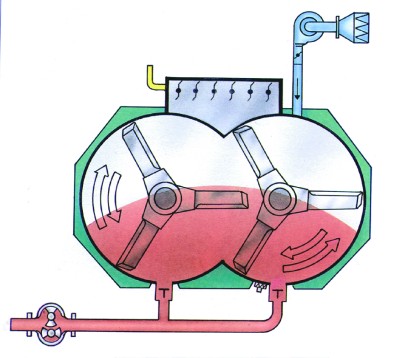

The first important step that was taken to speed up the conching process was making it a ‘dry’ process. Special conches have been designed for this, where the roller powder with a fat content of about 25% is, as it were, regularly turned, while the space above it is ventilated. The product is gradually heated by the frictional energy, which causes moisture and volatile acids to escape. Then cocoa butter is added in an amount sufficiently small to make a thick paste. Additional energy is also brought into the product by the stirring gear, and the higher the rotational speed, the more energy is added.

The stirring motion is important for breaking up the agglomerates, as well as contributing to the lubrication of the surfaces of the solid particles. The ultimate rheological properties of the chocolate are determined during this ‘plasticizing’ phase.

Figure 5.12: Frisse conche with heavy duty kneader arms

The last step of chocolate manufacturing is the addition of the remaining cocoa butter and lecithin to make the chocolate completely liquid. This phase is called wet-conching. At a reversed direction of rotation of the stirrers, and at very high speed, the chocolate is slapped against the walls, as in the traditional Längsreiber. Before further processing the product is checked for flavour and rheological properties.

Figure 5.13: Thouet conche

Figure 5.14: Carle-Montanari Homega conche

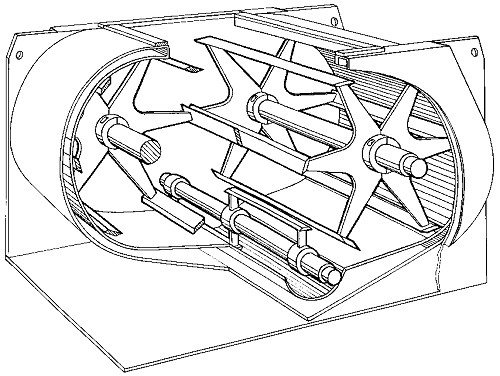

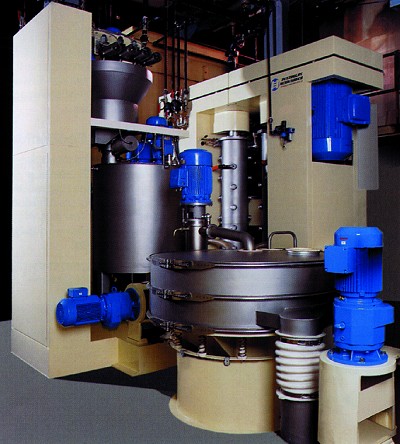

Continuous systems are the latest development in conching, for example, the Petzholdt Konti conche.

Figure 5.15: Konti conche (Petzholdt)

As was explained earlier, the ultimate properties of chocolate are largely determined by which conching method is applied. Chocolate manufacturers are, therefore, very secretive about the methods they use, as much as they are about the ingredients they include in their recipes, and the qualities and methods of processing they choose for their cocoa liquor mixtures.

Conching in the centrifugal refiner

Centrifugal refiners like the McIntyre refiner conche described earlier have a ventilator fitted at the top of the machine that is switched on when there is no more dry powder left. The ventilator ensures a continuous fresh stream of air over the chocolate, thereby de-moisturizing and de-acidifying the product, but to a lesser degree than in the other conches.

Flavour development in the ball mill

Conching can also take place in the ball mill. As this system is not suitable for the exchange of moisture, the intermediate tank is often equipped with a ventilator.

Sometimes, for instance, in systems like the Wiener, a rotating disc above the surface of the liquid produces a thin layer of material and this, together with the ventilation, aids moisture and acid removal from the chocolate. The ball mill offers only limited possibilities for influencing flavour development.

The necessity of conching can be reduced by using pre-treated or stripped cocoa liquor, i.e. moisture and acids have been removed from a thin cocoa liquor stream under vacuum.

|