|

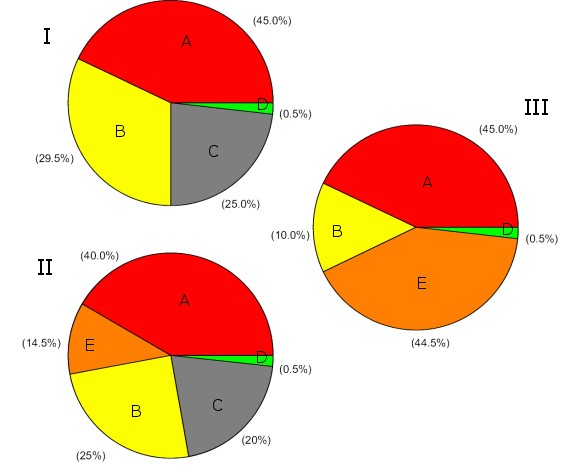

Chocolate is a dispersion of fine solid particles (cocoa, sugar and milk powder) in cocoa butter, another fat, or a combination of cocoa butter and another fat. The composition of chocolate is roughly as follows (see Figure 5.1):

Figure 5.1: Composition of white chocolate, milk chocolate and plain chocolate

A = sugar

B = cocoa butter

C = milk powder

D = other ingredients

E = cocoa liquor

Other raw materials can be used, apart from the above ingredients. Table 5.1 includes a number of raw materials that are commonly used in one country, while often being ignored in another. In Switzerland, for instance, hazelnut paste is usually added as an ingredient; in the UK crumb is often included in the chocolate recipe; while in France bitter chocolate with a very high cocoa liquor content (up to 75%) is preferred.

(In the table, X stands for ‘Commonly used’ and O for ‘May be used’)

Table 5.1: Summary of usual and possible ingredients in different countries

|

Country |

NL / B |

NL / B |

NL / B |

D |

CH |

GB |

GB |

GB |

F |

|

Ingrediënts |

Milk choco-late |

Plain choco-late |

White choco-late |

Cream choco-late |

Milk choco-late |

Milk choco-late |

Plain choco-late |

White choco-late |

Plain choco-late |

| |

|

|

|

|

|

|

|

|

|

|

Sugar |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

Cocoa mass |

X |

X |

|

X |

X |

X |

X |

|

XX |

|

Cocoa butter |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

Cocoa powder |

|

O |

|

|

|

|

O |

|

O |

|

CBE |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

Milk powder –high fat |

X |

|

X |

X |

X |

X |

|

X |

|

|

Milk powder – low fat |

O |

|

O |

|

O |

O |

|

O |

|

|

Lactose |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

Milk fat |

O |

|

O |

O |

O |

O |

|

O |

|

|

Whey powder |

O |

|

O |

|

O |

O |

|

O |

|

|

Blok milkpowder |

O |

|

|

|

O |

X |

|

|

|

|

Crumb (see page 166) |

X |

O |

|

|

O |

X |

|

|

|

|

Cream powder |

O |

|

O |

O |

O |

O |

|

O |

|

|

E442 |

O |

O |

O |

X |

O |

X |

X |

O |

O |

|

Lecithin |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

PGPR (see page 170) |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

Vanillin |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

Vanilla |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

Hazel nut pasta |

|

|

|

|

X |

|

|

|

|

The table gives an idea of the raw materials that can be used, however, legislation regarding the composition of chocolate has to be taken into account when preparing a recipe (see chapter 8).

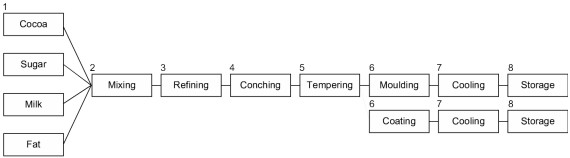

Chocolate manufacture is an industrial process, where a number of mechanical operations are needed to obtain the desired result. It normally includes four processing stages:

- thorough mixing of the raw materials;

- the refining of solid particles;

- thorough mixing of the refined solid particles and liquid fat

component(s) into a

homogenous product, both in terms of mouth feel and behaviour;

- further processing of the refined chocolate to obtain the desired end

flavour.

These four processes are discussed below.

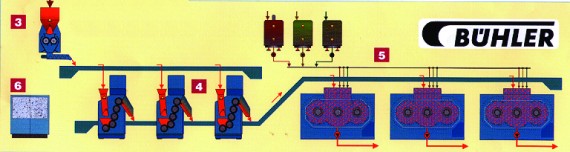

Figure 5.2: Schematic view of a processing line for the production of chocolate mass (blending ingredients, pre-rolling, roll refining, conching)

|

1 = ingredients

2 = mixer/kneader

3 = pre-roller (so called 2-roller)

4 = roller refiners

5 = conches

|  |

|

The production process from liquid chocolate to finished product can be a highly industrial one or a small-scale, traditional operation carried out by a confectioner. Paragraph 5.2 discusses this process.

Figure 5.3 Schematic process from ingredients to end product (Karlshamns)

|