|

Rheology is the science of the flow of matter, and examines the relationship between the stress on a material and the (relative) deformation (=strain) as a function of the time during which the stress is acting.

Three factors are relevant, i.e.:

- the stress acting on the material, i.e. the force per unit area;

- the strain of the material due to this stress (deformation);

- the time, both the total period of time during which the force is acting, and the period of time during which the stress changes.

Rheology is a descriptive science, i.e. it describes and characterizes how materials behave when being subjected to stress. Margarines must be spreadable, also straight from the refrigerator, and mayonnaise must be thick and creamy, whereas salad dressing should be liquid. Good-quality chocolate melts in the mouth, yet is solid at room temperature, and to ensure that raw materials flow smoothly through pipes and semi-finished products pour easily into moulds they must satisfy certain rheological properties.

In the case of chocolate, rheology has two major aspects, i.e. the viscosity and the yield value of the liquid product.

Other aspects involved are the chocolate’s textural and sensory properties, i.e. its appearance, smell and (full) mouthfeel, properties which can be perceived by the senses and are, therefore, called sensory properties.

The textural properties of chocolate are:

- hardness in the mouth, i.e. the strength required to break off chocolate with the teeth and tongue;

- meltability; the way in which chocolate melts completely in the mouth;

- smoothness; the degree of roughness or grittiness experienced when

chocolate melts in the mouth;

- stickiness; the degree to which the mixture of melted chocolate and

saliva sticks to the tongue and palate.

Viscosity and yield value

The rheological properties of liquid chocolate are measurable and can be expressed in two values: viscosity (h) and yield value(t).

Viscosity can best be described as the resistance felt when stirring a liquid, and yield value as the degree to which a drop of liquid flows outwards on a surface.

A low-viscosity chocolate is easy to pump and chocolate with a low yield value will pour easily into moulds.

The unit of viscosity is Pascal second (Pa.s), while, in practice, milli-Pascal second (mPa.s) is often used. One Pa.s = 1000 mPa.s. The unit of yield value is Pascal (Pa.)

The average values of liquid chocolate for (solid moulded) bars are:

- viscosity: between 1 and 20 Pa.s;

- yield value: between 10 and 200 Pa.

The average values of chocolate for enrobings are much lower:

- viscosity: between 0.5 and 2.5 Pa.s;

- yield value: between 0 and 20 Pa.

Measuring rheological properties

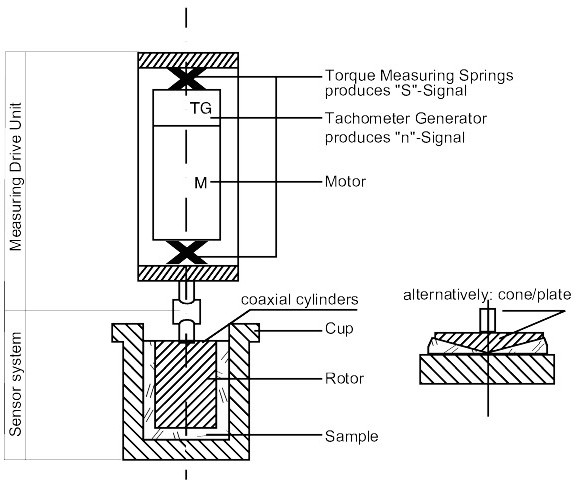

The rotational viscometer is the most frequently used instrument for measuring the rheological properties of chocolate, which measures the resistance a rotating cylinder, the rotor, encounters in a chocolate at a specific temperature (viscosity and yield value are temperature-dependent). The force required to start the rotor rotating is the yield value. Multipoint measurement, i.e. measurement at several speeds of rotation, is a good method for obtaining reliable exchangeable results, from which viscosity and yield value can be calculated.

This measurement can also be carried out in reverse by applying force to the cup of the viscometer and measuring the ensuing rotational speed. In addition to the viscometer, conical or other measuring instruments can be used, as well as simple empiric methods, which, however, are not exchangeable. (The OICCC, the International Organization of Cocoa and Chocolate Companies, has published an official method for measuring through viscosity and yield value. This method is clear and provides a great deal of information).

Figure 5.16: Rheology measuring cylinder

Viscosity and yield value are temperature-dependent but are also influenced by such factors as fat content, the quantity of lecithin, moisture content, particle size distribution and conching time:

- fat content: the greater the percentage of fat, the lower the viscosity and yield value;

- lecithin: added in a percentage of 0.1-0.3%, this emulsifier and, if

required, PGPR, has a viscosity decreasing effect similar to that achieved by adding 1-3% cocoa butter; adding quantities larger than the above will bring about a rise in yield value;

The type and quantity of the emulsifier influence the rheology. PGPR has a strong effect on the yield value. Dry conching influences the viscosity as well as the yield value.

- moisture content: the addition of only a (very) small quantity of water is sufficient for the viscosity and yield value to rise considerably;

- particle size distribution: the size distribution of the solid particles greatly influences the rheological properties of chocolate; the larger the particles, the lower the yield value, and also the lower the viscosity, but to a lesser degree;

- temperature (above the melting point of fat): a rise in temperature will cause

viscosity to decrease and yield value to rise;

- conching time: conching mainly affects the yield value, which decreases considerably particularly during the first hours of conching.

Cost price

Fat (cocoa butter and sometimes milk fat) is one of the more expensive raw materials in the chocolate recipe, yet necessary in a certain amount to give the chocolate the required processing properties and its ultimate flavour. Manufacturers, however, try to keep the percentage of fat as low as possible.

|