|

As cocoa products are mostly used as foodstuffs for human consumption, they must meet the highest microbiological standards to avoid the risk of deterioration that could cause illness in the consumer. To achieve this, high standards are set for the production of cocoa products, which also contributes to the shelf life of the end product.

This section describes the fields of application of the various cocoa products, with the focus on cocoa powder as this is used in a great many products. The use of cocoa butter and cocoa liquor is limited to a few products, chocolate being the most important.

Cocoa butter

No less than 99% of cocoa butter produced worldwide is used for chocolate manufacture.

The butter supplied to the user must have product characteristics that satisfy his requirements in terms of flavour, aroma, solidification behaviour and hardness, all characteristics that can be laboratory tested.

Cocoa butter flavours range from neutral, i.e. no flavour at all, to a distinctly perceivable cocoa flavour. The latter type is suitable for use in white chocolate, while deodorized cocoa butter, i.e. butter from which off-flavours but also the cocoa flavour have been removed, is usually preferred for use in most other types of chocolate. Neutral-flavour cocoa butter enables chocolate manufacturers to tailor a specific home-flavour through blending with a specifically selected cocoa liquor.

Flavour index measurement carried out in the laboratory produces information on the cocoa flavour intensity of the butter, while tasters have to judge the butter on such other flavour aspects as off-flavours.

When used in chocolate, cocoa butter must have a certain degree of hardness. The types of bean from which cocoa butter is processed determine its hardness: beans of Brazilian origin produce a soft butter, whereas Malaysian beans make a hard butter. A good measure for the hardness of the butter is the iodine (addition) value.

Cocoa butter is also used in the pharmaceutical and cosmetics industry, in suppositories and in creams respectively.

Cocoa liquor

Cocoa liquor is pressed into cocoa butter and cocoa cake, the latter being refined into cocoa powder. Cocoa liquor is one of the raw materials used in chocolate manufacture. At one time manufacturers used to press their own cocoa liquor, but now they tend to buy it as a raw material from suppliers, who are able to deliver liquors tailored to specific user requirements in terms of flavour and other properties by selecting the right type(s) of bean as well as choosing the proper roasting and refining conditions. Chapter 5 describes the manufacture of chocolate, as well as describing the raw materials and additives used in this process.

Cocoa powder

Most people relate the use of cocoa powder to chocolate flavoured milk, but there are a great many other products in which it is used.

Cocoa powder is used for its two major properties: its contribution towards, one, the flavour and, two, the colour of a product. The user also influences the colour by the processing method and the choice of ingredients in the recipe.

The colour of the cocoa powder affects the colour of the user’s end product. Colour being such an important aspect of cocoa powder, this subject is dealt with here in more detail.

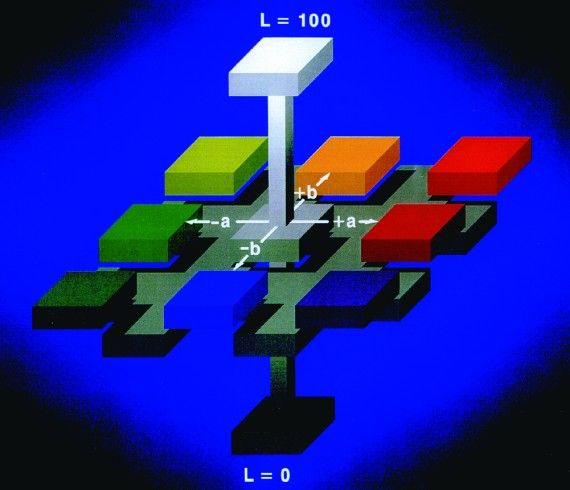

The colour of an object is determined by three factors, i.e. the object itself, the light source that is used, and the observer, being either a person who makes a visual judgment, or a colour meter that produces a measurement that excludes any subjectivity involved in human observation. The measuring results of the colour meter can be expressed in various ways via a number of mathematical calculations. A frequently used representation is the one established by the Commission Internationale de l’Eclairage (CIE), where the colour is a three-dimensional point: L*, a* and b*.

Figure 6.1: Illustration of colour measurement indices

L* shows the difference between light and dark (100 = white and 0 = black),

a* shows the difference between red and green (+ a* = red and - a* = green) and

b* shows the difference between yellow and blue ( + b* = yellow and – b* = blue).

It has to be taken into account that the values found for L*, a* and b* may differ for the several types and makes of colour meters and that, other than values like pH, they may not be regarded as absolute values that can be compared and exchanged as such.

Regarding the colour of cocoa powder we differentiate between extrinsic or external colour and intrinsic or internal colour. The extrinsic or external colour of cocoa powder is the colour we see when we open a package containing this powder. It is influenced by the percentage of fat in the powder, while good stabilization of the fat also plays a role. Intrinsic or internal colour shows when cocoa powder is dissolved in, for instance, water, and is hardly affected by the percentage of fat in the powder.

The consistency of such cocoa powder properties as colour, acidity (pH), fineness and fat content is important in all applications, as this ensures a consistency in appearance of the end product. This is desired by both the user of the powder and the consumer of the chocolate product, as well as contributing to the specific application by the user. Variations in these properties may lead to poor-quality end products.

The fat content of cocoa powder is also important in terms of nomenclature, i.e. whether an end product may be designated as ‘chocolate’ or not. In many countries the term ‘chocolate’ may not be used in the name of a product unless the percentage of cocoa butter in the cocoa powder is at least 20%.

The use of cocoa powder in chocolate milk has been mentioned earlier, and cocoa powder is supplied to the dairy industry for this and other products. For chocolate milk, such factors as pH and fineness of the powder are important. An incorrect pH value may cause the milk to curdle, and coarse-grained powder may lead to an undesirable degree of sedimentation of the cocoa powder.

The percentage of shell particles in cocoa powder for the dairy industry should not be too high in order to prevent this causing damage to the equipment, and accelerating wearing out of the heads of the homogenizer.

Manufacturers aim at producing dairy products that are consistent in colour and, therefore, attach great importance to the intrinsic colour of the powder as this determines the colour of the chocolate milk.

Stabilizers, i.e. thickening agents, are often added to the cocoa powder in order to keep the cocoa particles in suspension and to prevent them from sinking. In order to obtain a good end product it is important that the right quantity of stabilizer is added: too low a percentage will fail to bring about the desired effect, whereas too large a percentage may have adverse effects. Another important factor to be taken into account is the variation that may occur in the composition of the milk, depending on the season.

Cocoa powder is also used in such desserts as mousses and puddings. Here pH is important, as well as the fineness of the powder: coarse-grained powder produces visible dark spots. A constant cocoa-powder colour is important for the ultimate colour of the dessert, while the flavour of the cocoa powder contributes considerably to the flavour of the end product.

The presence of too many iron particles in the cocoa powder used in these products may have an adverse and undesirable effect in that the end product may show black spots with purple threads around them that look like mould.

Cocoa powder also has wide applications in the ice-cream industry, where the fineness of the powder is important for influencing the crystallization process of the ice cream. Coarse particles may produce unwanted dark specks.

Cocoa powder is also an ingredient in instant chocolate products, for example, powders that can be suspended in milk or water, and are used for making instant chocolate drinks. In instant products cocoa powder is usually adhered to the sugar grains. The suspensibility of powder in water or milk can be improved by using lecithinated cocoa powder, but care should be taken that lecithin is added in the correct amount, usually 1-5% (based on cocoa powder).

Related to this last application is the use of cocoa flavoured powder mixes in vending machines, where hot water is added to the vending mix, i.e. a mixture of cocoa powder, sugar and milk powder, to produce a chocolate drink.

In the baking industry cocoa powder is used in flour confectionery, often in cakes and biscuits. All the cocoa properties must be constant here as minor variations may disturb the baking process and produce undesirable results in the form of, for instance, shrunken or collapsed bakery products. Any remnants of potash (used in the cocoa alkalization process) left in the powder affect the baking agents used as leavening agents. As most consumers dislike variations in a product, changes in the recipe should be made gradually. A baker’s preference for a certain type of cocoa powder is mainly determined by the colour and flavour offered by the powder.

It is also worth mentioning the application of defatted cocoa powders, i.e. cocoa powders with a fat content below 1%, which are suitable for low-calorie and low-fat products, and as such were first introduced as an ingredient in low-fat ice cream, as well as in products where fat has an adverse effect on the texture of the product. An example of this is meringue, a product based on egg white. The fat present in the cocoa powder disturbs the stable foam of whipped egg white, causing it to collapse. Defatted cocoa powder prevents this taking place, yet produces a cocoa-flavoured meringue product.

It should be taken into account that the quantity of defatted cocoa powder used in low-fat formula’s is usually quite small. This means that the difference in fat contribution between a defatted cocoa powder and a cocoa powder with a fat content of 11% is not very significant.

Other products in which cocoa powder is used as an ingredient are chocolate syrups, coatings, sauces, creams, pastes and typical American products like brownies (dark-brown cakes with a strong cocoa flavour and a high moisture content); frosting (topping on cakes and pastries), and hot fudge sauce (hot chocolate syrup).

|