|

Prior to further processing beans must be cleaned as, due to the methods of fermentation and drying applied in the countries of origin, they usually contain a wide variety of non-cocoa components, such as sand, stones, wood and metal swept up with the beans from the ground. Foreign material may make up no less than one per cent of the total quantity of the product supplied, depending on the country of origin.

Cleaning the beans is a four-step process:

1. sieving;

2. removal of light components;

3. removal of metal particles using magnetic separators;

4. removal of heavy components.

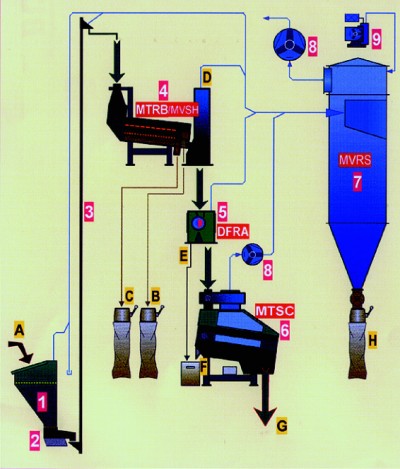

The scheme of a complete bean cleaning process looks as follows:

Figure 2.1: Schematic view of bean cleaning equipment (Bühler)

1. filling bunker

2. dosing device

3. bucket elevator

4. cleaning unit

5. rotating magnet

6. de-stoner

7. aspiration filter

8. aspiration fan

9. scavenging

(air exhauster)

A. bean inlet

B. coarse-grained material

C. grit fraction

D. light components

(dust, shells)

E. iron particles

F. heavy components

(stones, glass)

G. clean product

H. filter dust |

|

The beans automatically fed from the silos are usually weighed first before they are fed into the cleaning machine with 4 cleaning phases:

- The vibrating sieve consists of two screens of different sized mesh.

The upper screen sieves out foreign matter larger than a normal bean size, such as double beans, bean clusters and fibrous matter, while letting whole and broken beans fall onto the lower fine mesh screen that allows the so-called ‘grit fraction’ (small particles such as sand grains) through.

When a band sieve is used, only the coarse matter is removed.

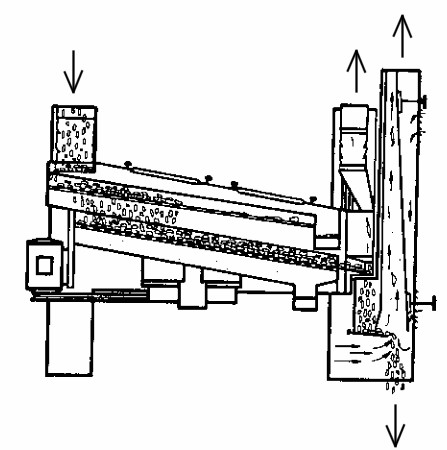

Figure 2.2

- The beans collected on the lower screen are fed in measured quantities to the

aspiration or suction channel immediately connected to the screen for the

removal of light components like loose shells, fibrous matter and insects.

- Any (magnetic) iron particles are removed as the beans pass the magnetic separators.

- The de-stoner separates stones and other heavy material from the beans. Air is blown in from the bottom through a bed of beans on a sloping screen vibrated upwards whereas the beans, which are lighter, remain at the lower end. Stones and beans are collected separately.

Figure 2.3

Adjustable valves in the exhaust system regulate the entire system’s air control while a filtering installation ensures the discharge of dust-free air.

|